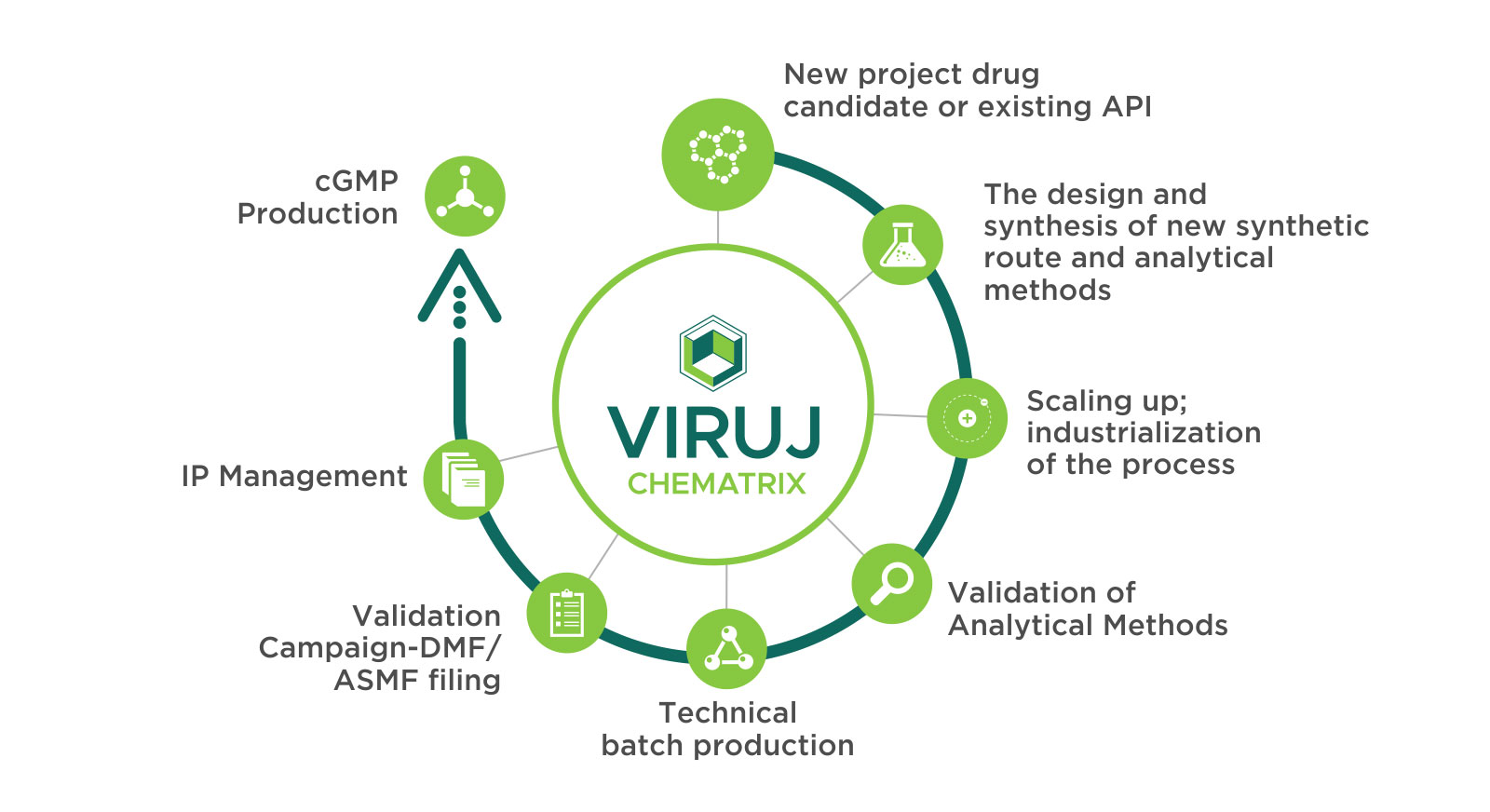

At VIRUJ CHEMATRIX, we custom synthesize niche products for the Healthcare, Agro, Veterinary and Electronic Chemical segments.

Our work on complex molecules opens up possibilities for companies world over.

Biocatalysis have an environmental-friendly nature, high efficiency, and remarkable selectivity for reactions. However, enzymes, which are powerful catalysts used in biocatalysis, suffer from low stability when used for long-term operations in solution and a gradual decrease in activity during storage. In Continuous Flow Technology Microfluidic reactors are devices known for their smaller dimensions, large surface-to-volume ratios, and well-defined reaction times. Enzymes immobilized in such microfluidic reactors can exhibit distinct benefits, such as fast reaction rate, high storage stability, suppressed autolysis, and ease of use. The use of microfluidic immobilized enzyme reactors (μ-IMERs) offers several advantages over traditional technologies in performing biocatalytic reactions, such as low energy consumption, rapid heat exchange, fast mass transfer, high efficiency, and superior repeatability.

Continuous flow technology (flow chemistry) offers several advantages to peptide synthesis. Using Continuous Flow Synthesis or Flow Chemistry, it is straightforward to pre-heat and preactivate the amino acid. . This ensues fast, more efficient coupling cycles. This approach vastly increases the speed of each coupling cycle. Complete coupling and deprotection cycles of just 15 minutes are easily achieved. This efficient coupling also greatly reduces the need for excesses of reagent. This reduces the cost and amount of waste generated by the synthesis. Integration of inline real-time analysis, such as UV/ Vis spectroscopy and Variable Bed Flow Reactor into the flow after the reactor permit immediate identification of any nonstandard coupling events. This allows the user to recognise and optimise difficult coupling aevents during small scale syntheses. The peptide synthesis can then be scaled up using the optimised sequence.

In HPI product or preparation of APIs, handling of toxic and hazardous gases or chemicals is difficult. In Continuous Flow Technology, it is easy to handle

hazardous and toxic chemicals and gases in continuous flow reactor in laboratory as well as industrial scale. For industrial scale, with respect to safety, Continuous Flow Technology is one of the good techniques for handling hazardous reactions such as - chlorination, fluorination, sulfonation Nitration, hydrogenation etc.

Biocatalysis have an environmental-friendly nature, high efficiency, and remarkable selectivity for reactions. However, enzymes, which are powerful catalysts used in biocatalysis, suffer from low stability when used for long-term operations in solution and a gradual decrease in activity during storage. In Continuous Flow Technology Microfluidic reactors are devices known for their smaller dimensions, large surface-to-volume ratios, and well-defined reaction times. Enzymes immobilized in such microfluidic reactors can exhibit distinct benefits, such as fast reaction rate, high storage stability, suppressed autolysis, and ease of use. The use of microfluidic immobilized enzyme reactors (μ-IMERs) offers several advantages over traditional technologies in performing biocatalytic reactions, such as low energy consumption, rapid heat exchange, fast mass transfer, high efficiency, and superior repeatability.

Continuous flow technology (flow chemistry) offers several advantages to peptide synthesis. Using Continuous Flow Chemistry, it is straightforward to pre-heat and preactivate the amino acid. This ensues fast, more efficient coupling cycles. This approach vastly increases the speed of each coupling cycle. Complete coupling and deprotection cycles of just 15 minutes are easily achieved. This efficient coupling also greatly reduces the need for excesses of reagent. This reduces the cost and amount of waste generated by the synthesis. Integration of inline real-time analysis, such as UV/ Vis spectroscopy and Variable Bed Flow Reactor into the flow after the reactor permit immediate identification of any nonstandard coupling events. This allows the user to recognise and optimise difficult coupling aevents during small scale syntheses. The peptide synthesis can then be scaled up using the optimised sequence.

In HPI product or preparation of APIs, handling of toxic and hazardous gases or chemicals is difficult. In Continuous Flow Technology, it is easy to handle hazardous and toxic chemicals and gases in continuous flow reactor in laboratory as well as industrial scale. For industrial scale, with respect to safety, Continuous Flow Technology is one of the good techniques for handling hazardous reactions such as – chlorination, fluorination, sulfonation Nitration, hydrogenation etc.

| S.No. | APIs | CATEGORY | INDUSTRY SEGMENT |

|---|---|---|---|

| 1 | 2,3-DICHLORO-5,6-DICYANO-1,4-BENZOQUINONE | OXIDISING REAGENT | PHARMA |

| 2 | INDAZOLINE DERIVATIVES | INTERMEDIATES FOR API | PHARMA |

| 3 | 6-CHLORO-2-METHYL-2H-INDAZOL-5-AMINE | INTERMEDIATES FOR API | PHARMA |

| 4 | URACIL | INTERMEDIATES FOR API | PHARMA |

| 5 | CIS-4-OCTANE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 6 | FERRIC TRI MALTOL | IRON SUPPLEMENT | PHARMA |

| 7 | CHLORO METHYL URACIL | INTERMEDIATES FOR API | AGRO & PHARMA |

| 8 | DIPHENYLAMINE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 9 | URIDINE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 10 | 1,4-BENZOQUINONE | OXIDISING AGENT | PHARMA |

| 11 | DI-TERT-BUTYLCHLOROPHOSPHINE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 12 | METHYL N-BOC-L-PROLINE-3-ENE | INTERMEDIATES FOR API | PHARMA |

| 13 | 2,6-BIS-[1-(2-TERT-BUTYLPHENYLIMINO)-ETHYL]PYRIDINE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 14 | PENDIMETHALIN | INTERMEDIATES FOR API | AGRO |

| 15 | PROPAN-2-ONE AZINE / ACETONEAZINE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 16 | ACETOPHENONE AZINE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 17 | 1,3-DIIODO-5,5-DIMETHYLHYDANTOIN | REAGENT | AGRO & PHARMA |

| 18 | PYROXASULFONE | INTERMEDIATES FOR API | AGRO |

| 19 | O-ALLYL 2,2,2-TRICHLOROACETIMIDATE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 20 | BENZYL 2,2,2-TRICHLOROACETIMIDATE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 21 | TERT-BUTYL 2,2,2-TRICHLOROACETIMIDATE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 22 | 4-METHOXYBENZYL-2,2,2-TRICHLOROACETIMIDATE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 23 | METHYL 2,2,2-TRICHLOROETHANIMIDATE | INTERMEDIATES FOR API | AGRO & PHARMA |

| 24 | 3-HYDROXY-4-CHLORO-2PYRIDINECARBOXYLIC ACID / 4-CHLORO-3-HYDROXYPICOLINC ACID | INTERMEDIATES FOR API | AGRO & PHARMA |

Disclaimer: None of the products will be supplied to the countries wherein there could be conflict with existing patents/laws. However, the final responsibility lies exclusively with the buyer/partner.

| S.No. | API's | Category | Industry Segment | Action |

|---|---|---|---|---|

| 1. | DICYANO DICHLORO QUINONE | OXIDISING REAGENT | Pharma | Know More |

| 2. | INDAZOLINE DERIVATIVES | INTERMEDIATES FOR API | Pharma | Know More |

| 3. | URACIL | INTERMEDIATES FOR API | Pharma | Know More |

| 4. | CIS-4-OCTANE | INTERMEDIATES FOR | Agro | Know More |

| 5. | FERRIC TRI MALTOL | IRON SUPPLEMENT | Pharma | Know More |

| 6. | CHLORO METHYL URACIL | INTERMEDIATES FOR API | Agro & Pharma | Know More |

| 7. | DI PHENYL AMINE | INTERMEDIATES FOR API | Agro & Pharma | Know More |

We help clients from world over develop, manufacture and innovate their small molecule medicines through our flow and batch synthesis.